Expertise

What is an insect killer?

The insect killer, an effective fly trap.

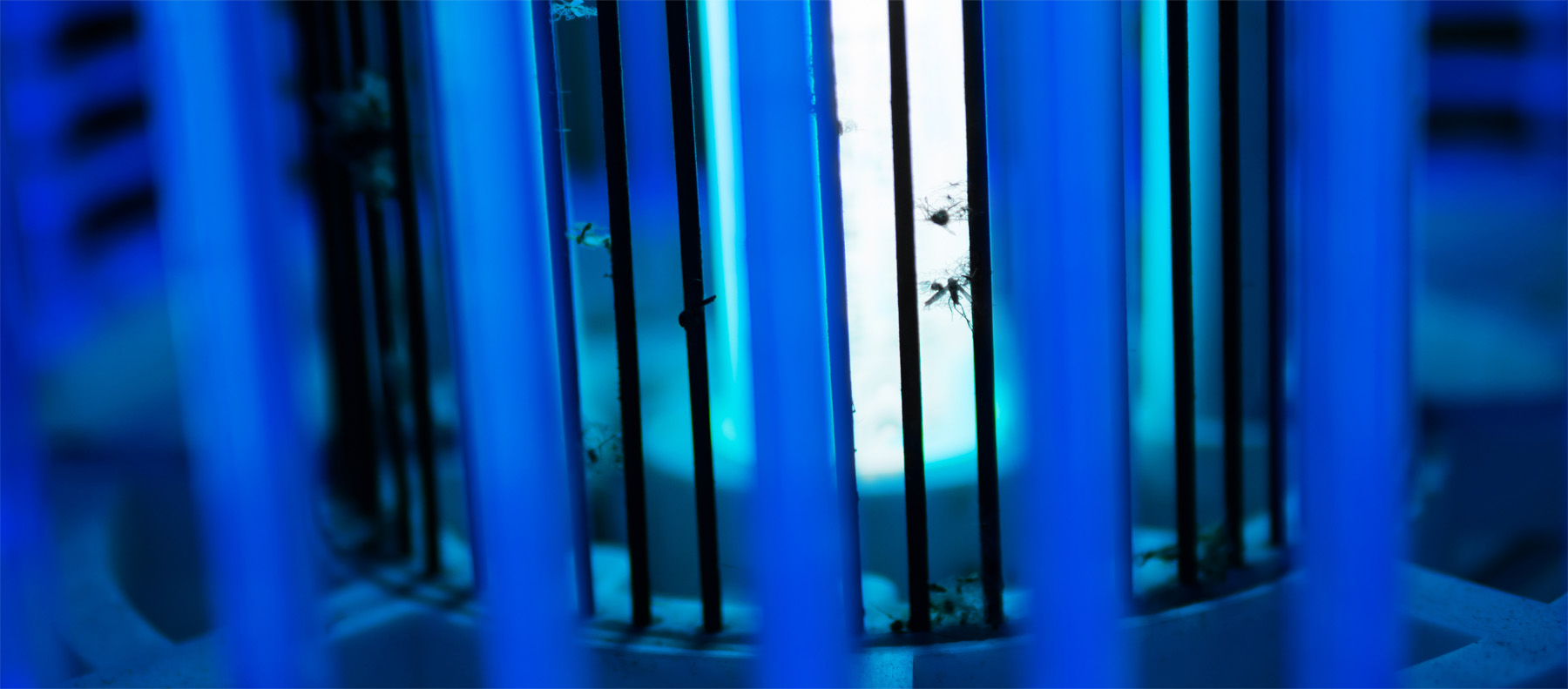

Fly killers, also known as electric fly traps, are a professional solution to effectively eliminate flies.

An electric insect killer (also called a fly killer or insect trap) is an essential device for getting rid of pests. By attracting and electrocuting flies and other flying insects, your food areas remain hygienic and free of unwanted insects.

An insect killer is a luminous electric device

with ultraviolet rays

which attracts flying insects and then destroys them, either by electrification or by gluing.

The insect killers work with powerful lamps emitting UVA light, the trap becomes very attractive for flies, as well as for many other flying insects.

There are 2 families of insect killers, each with a different method of elimination:

Sometimes simply called glue traps, these insect killers will attract flies, which by circling the lamps the insects are captured by an adhesive plate.

This type of fly trap requires a little maintenance (the adhesive strips must be changed regularly), it has the advantage of being completely silent.

Attracting insects with its UV lamps, the electric insect killer or destroyer has a powerful electric grid that will eliminate by electrocution the insects touching it. Destruction by electrification: the insects are struck by a high voltage grid fed by a transformer supplying this high voltage at low intensity. The insects are collected in a removable tray at the bottom of the device.

Lighting

What attracts insects in an IVD?

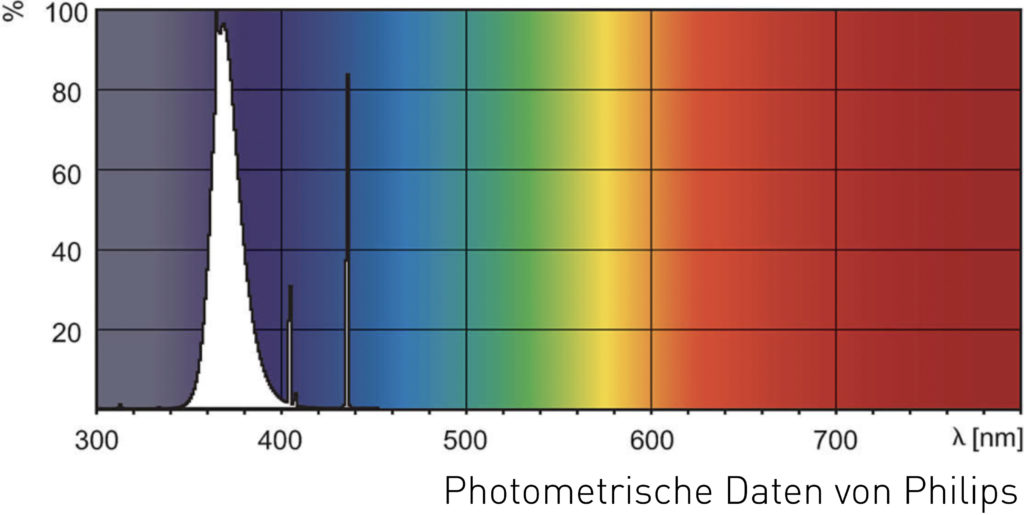

Insects are attracted to UVA radiation (between 315 and 400 nm), with a peak attraction at 368 nm.

Our flying insect killers are equipped with lamps or UVA tubes that reproduce the highest UVA attraction peak.

Once the insect is attracted by the light, it is destroyed in 2 different ways: by glue or by electricity.

Philips photometric data

What is the life span of a lamp and a UVA tube?

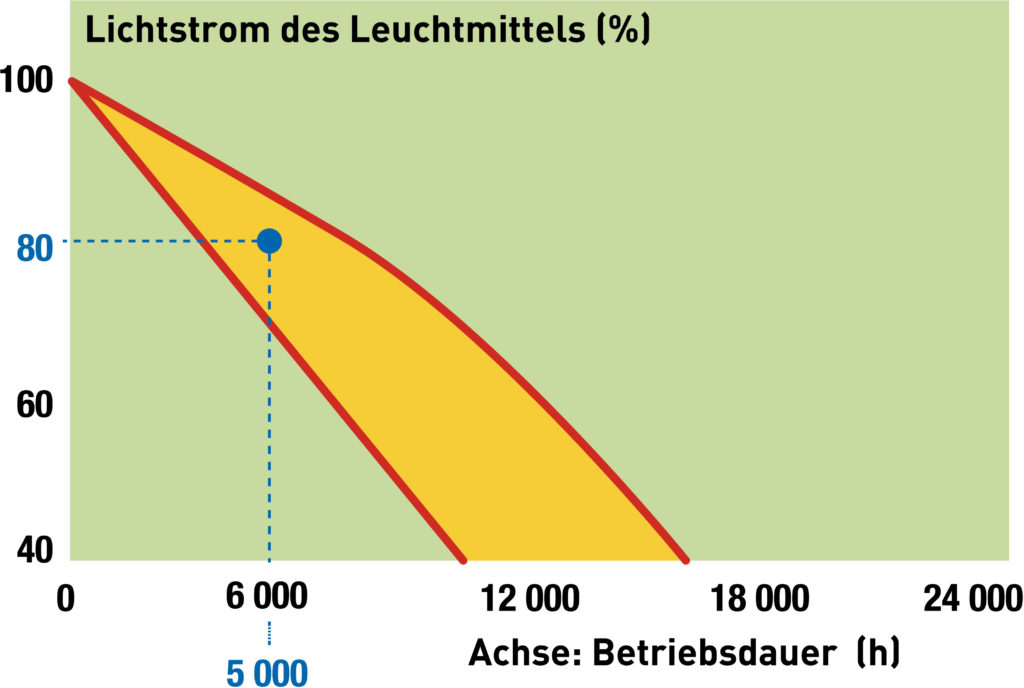

The average life of a lamp is 9,000 hours. However, the luminous flux of a lamp gradually decreases. The useful life is the number of hours after which a lamp emits only 80% of its light output. This is 5,000 hours (6 to 7 months), the recommended time after which a lamp should be replaced to maintain optimum efficiency.

To go further…

BRC offers a range of LED lighting. Using this technology allows you to reduce your electricity consumption by half compared to conventional actinic lighting.

Even though the purchase price of LED tube/light is higher, their service life is much longer (2 years warranty for tubes and 3 years warranty for lamps).

Our LED lighting range can be mounted on all BRC insect killers equipped with fluorescent tubes, without any modifications.

As an option or standard, the high quality Teflon® (PTFE) sheaths prevent any risk of glass splinters being projected while maintaining the intensity of the light.

- 96.5% transmission of UVA rays (and 89% of UVC)

- High resistance to extreme temperatures (+ 200° C) and aggressive environments

- Lifetime on UVA lamps: 1 year

- Eliminate the risk of glass and mercury contamination and the risk of injury

- HACCP recommendations

Protection class

What is a protection index?

The protection rating represents a level of protection provided by the enclosure of an electrical device. Its definition is recorded in an international standard of the Electrotechnical Commission, relating to the sealing.

The protection rating is indicated by two letters “IP”, followed by two numbers that vary.

- The first number indicates a level of protection against solid objects.

- The second number indicates a level of protection against liquids.

What is the protection rating of my BRC device?

The products that BRC sells can be adapted to different environments and aggressive conditions. We offer 5 types of protection:

Protects the device against solid objects larger than 12 mm and no protection against liquid objects.

Protects the device against solid objects larger than 12 mm and against vertical drops of water.

Protects the unit from dust and water splashes from all directions.

Fully protects the unit against dust and water jets from all directions (22.5 mm nozzle, 12.5 l/min).

| INDICE IP 65 | DEGRÉ DE PROTECTION contre la pénétration des corps solides | DEGRÉ DE PROTECTION contre la pénétration des corps liquides |

|---|---|---|

| 0 | Pas de protection | Pas de protection |

| 1 | Protégé contre la pénétration de corps étrangers solides de plus de 50 mm | Protégé contre les chutes verticales de gouttes d’eau |

| 2 | Protégé contre la pénétration de corps étrangers solides de plus de 12 mm | Protégé contre les chutes verticales de gouttes d’eau avec surface d’impact inclinée d’un maximum de 15° |

| 3 | Protégé contre la pénétration de corps étrangers solides de plus de 2,5 mm | Protégé contre les chutes verticales de gouttes d’eau avec surface d’impact inclinée d’un maximum de 60° |

| 4 | Protégé contre la pénétration de corps étrangers solides de plus de 1 mm | Protégé contre l’eau provenant de toutes les directions |

| 5 | Protégé contre la poussière (pas de dépôt nuisible) | Protégé contre un jet d’eau dirigé de n’importe quel côté (aucun effet nuisible) |

| 6 | Protection totale contre la poussière | Protégé contre des jets d’eau puissants dirigés de n’importe quel côté (aucun effet nuisible) |

| 7 | Protégé contre les effets d’une immersion entre 15 cm et 1 m | |

| 8 | Protégé contre une immersion prolongée sous pression |

INOX

What are the different types of stainless steel used at BRC?

Stainless steel is mainly composed of iron, nickel and chromium alloys. The strength of stainless steel comes mainly from its composition. BRC offers different types of stainless steel that can be used under different conditions.

- Stainless steel 430 composed of 17% chrome (food grade stainless steel).

- Stainless steel 304 composed of 18% chrome and 10% nickel (food grade stainless steel).

- Stainless steel 316 composed of 18% chromium and 13% nickel, 2% molybdenum, known as “marine stainless steel”, used in the chemical, pharmaceutical, petroleum and food industries, as well as intensively in the nautical field

| Inox | Cr | Ni | Mo | Milieu |

|---|---|---|---|---|

| 430 | 17% | Industries agroalimentaires, cuisines | ||

| 304 | 18% | 9% | + industries chimiques | |

| 316 | 18% | 13% | 2% | + industries pétrolières, pharmaceutiques, milieu marin |

How to choose the quality of its stainless steel, according to your environment?

I want to store my equipment in a room protected from humidity, I choose 430 series stainless steel.

430 stainless steel contains a very small amount of nickel. With little resistance to corrosion, it is ideal for less demanding environments.

I wish to store my BRC device in an environment where there is water splashing, cleaning with water, possible contact with food on the device, I choose 304 series stainless steel

Stainless steel 304 is the most commonly used type in the food industry. It has a brilliant shine due to a high level of chrome and nickel. It is highly resistant to corrosion and rust, although it is susceptible to corrosion caused by exposure to salt.

I want to store my BRC device in an environment where I work with seafood or chemicals, I choose 316 series stainless steel

It is the second most common type of stainless steel and its alloy includes an additional element, molybdenum, which increases its resistance to corrosion caused by salt and other chemicals.

IOT

“The many possibilities of IoT have dictated that we choose technologies that address unmet needs to generate more value than just traps.”

BRC INTEGRATES NEW TECHNOLOGIES INTO ITS PRODUCTS IN AN APPROPRIATE MANNER.

IoT in industry

At BRC, we support our customers’ development through innovation. This contribution of competitiveness stimulates their growth and consequently ours. We create technologies that serve our customers and adapt to their practices, not the other way around. Our project methodology is based on 3 pillars: monitoring of new technologies, analysis of customer needs and projection of expected benefits. In this context, the notion of “IoT” (Internet of Things) and the needs of our customers have given rise to several ideas in our business.

Which IoT functions for Pest Control?

The IOT functions that contribute to our customers’ competitiveness are: performance measurements, status indicators, alert thresholds, repetitive operations and failures. The service provided by the traps is the capture of unwanted flying insects. Catch counts therefore measure the performance of the service provided. The saturation rate of the glue plates indicates the status of the remaining capacity.

The indexing of a configurable alert threshold on this rate allows to optimize this repetitive task of changing plates. This makes it easier to replace them when necessary, avoids unnecessary costs due to premature replacement and improves service continuity by eliminating already saturated plates. We have also included alerts for the most common causes of failure, power failure and UVA source malfunction.

BRC responded to the market with the innovative TrapManager® device that allows PCOs to monitor their trap fleet. Equipped with an HD camera, he photographs the glue sheet 5 times a day. It then counts the captures and calculates the saturation rate of the plate. Via 3G, it then sends this data and the status of the device to the BRC server. This information then allows PCOs to provide a unique consulting service.

They may indicate symptomatic variations of an abnormal infestation. The user can then look for the cause and make corrections to preserve his production. It also provides unparalleled traceability to meet HACCP practices and regulatory requirements.

BRC product regulations

BRC products meet European and international requirements and comply with CE, UKCA and IECEE standards.

BRC declares that all these electrical appliances comply with the provisions of the European directives:

2002/96/EC (WEEE: Waste Electrical and Electronic Equipment)

2014/30/EU (EMC: electromagnetic compatibility)

2014/35/EU (Low voltage)

2011/65/EU (RoHS2 : Restriction of hazardous substances)

ATEX

The ATEX directive (ATmospheres EXplosives) aims at reinforcing the protection in atmospheres with a high organic dust content and/or risk of explosion by the implementation of technical and organizational measures.

BRC offers the VORTEX insect killer, whose components are protected by an unbreakable quartz glass that ensures excellent transmission of UVA rays. The VORTEX is designed for zones 1-21 and 2-22.

CEM

The EMC Directive 2014/30/EU of the European Parliament and of the Council contributes to the CE marking with regard to electromagnetic compatibility (EMC). The objective of the EMC directive is to maintain a healthy electromagnetic environment by ensuring that different electrical and electronic devices can coexist harmoniously.

IECEE

| Signification | Identification Gaz/Vapeurs | Identification Poussières |

|---|---|---|

| ATEX présente en permanence en fonctionnement normal | Zone 0 | Zone 20 |

| ATEX présente occasionnellement en fonctionnement normal | Zone 1 | Zone 21 |

| ATEX présente en cas d'accidents ou de dysfonctionnement | Zone 2 | Zone 22 |

The European directive RoHS (Restriction of hazardous substances in electrical and electronic equipment) 2002/95/EC aims to limit the use of six hazardous substances in electrical and electronic equipment: lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE)

In response to the decree 2005-829 called "WEEE", which requires producers of electrical and electronic equipment to organize the rigorous elimination of waste from products put on the market since August 2005, BRC to integrate the eco - contribution in conditions that comply with the regulations and respect the environment.

The HACCP method (Hazard Analysis Critical Control Point) allows the identification, evaluation and control of hazards with regard to food hygiene. The HACCP allows to be in conformity with the law. All BRC product features (insect killers and hygiene equipment) meet HACCP requirements.

The IFS Food certification is the essential prerequisite for access to the French, German and Italian mass market. It allows you to prove your control of the safety and hygiene of your private label processed food products. It is based on the ISO 9001 standard and the HACCP system.

The BRC standard, recognized by the Global Food Safety Initiative (GFSI), aims to harmonize food safety standards with the support of the world's largest retailers and food manufacturers. GFSI recognition means that you can use the BRC global standard to meet the requirements of these major players under a single, internationally recognized food safety management system.

This device is applicable to organic materials and objects as well as to accessories and sub-assemblies of accessories consisting of at least one organic component coming into contact with water. The Sanitary Compliance Certificate (ACS) is an official approval issued by the General Directorate of Health, which has become mandatory in France since December 24, 2006.